Condensate neutralizers are crucial for treating acidic condensate from high-efficiency heating appliances. Without a neutralizer, condensate has the potential to corrode a building’s foundation, floors, and drainage system. Properly installing a neutralizer is fundamental, but only part of the solution. Like heating appliances require regular maintenance, condensate neutralizers must also be routinely serviced by replacing the neutralizing media — part two of the preventative solution to protect against expensive corrosion.

How Long Does Neutralizing Media Last?

A well-designed neutralizer can perform effectively with high-efficiency appliances for years, provided the neutralizer is routinely inspected and the media is regularly changed.

The recommended replacement schedule for neutralizer media varies depending on myriad factors, such as the acidity and volume of the condensate leaving your high-efficiency appliance. Condensing heating appliances can create a particularly concentrated amount of nitric, sulfuric, sulfurous, and hydrochloric acid in their condensate.

To ensure timely replacement of neutralizer media, operators or service technicians must regularly test the pH of the treated condensate leaving the neutralizer. Not all neutralizer media is created equal though. As a general rule of thumb, you should change condensate neutralizer media approximately once or twice a year.

What Is Neutralizing Media?

The pH neutralization process occurs as acids in the condensate react with an alkaline agent (e.g. calcium carbonate, magnesium oxide) through intimate surface contact. The reaction is not instantaneous though, making surface area and sufficient contact time with the agent critical. We refer to this crucial time required for sufficient neutralization as “soak time”.

Limestone

Rudimentary neutralization solutions utilize limestone or marble chips to treat corrosive wastewater streams in various applications. In the heating and plumbing industries, the early neutralizers adopted the old school use of such media. However, as the industry came to realize, limestone is not well-suited for the demands of today’s high-efficiency heating appliances.

The primary compound in limestone is calcium carbonate. When the calcium carbonate reacts with acidic condensate, it forms carbon dioxide, water, and insoluble salts. These salts coat the resulting limestone, impairing the further neutralizing effect of the media. As a result, limestone media is quickly rendered ineffective and must be replaced.

Further, due to its lower efficacy, limestone requires much more surface area and soak time, requiring more physical holding space or capacity for sufficient soak time. Today’s high-efficiency appliances produce condensate that is (i) highly acidic (pH between 2.9 and 4.0) and (ii) in large volumes (measured in gallons per hour). Moreover, these appliances are installed in operating conditions where space is limited and the physical footprint must be minimized (e.g. basements, wall-hung). It is important to select a neutralizer that not only has the appropriate configuration and capacity for your appliance, but also is designed with effective neutralizing media – a complete solution.

pH Power Pellets®

CBM-227 inline tube neutralizer

CBM-227 inline tube neutralizer

JJM® neutralization solutions are purpose-built and designed to perform, ensuring the sufficient “soak time” for critical heating and plumbing applications. Further, JJM® utilizes its pH Power Pellets®, the proprietary neutralizing media found exclusively in JJM® products. The active ingredient in pH Power Pellets® is magnesium hydroxide, which results in a powerful, fast-acting media. With a pebble-like design, pH Power Pellets® are produced to maximize surface contact and provide layers of neutralization power without the insoluble salts of limestone. As such, pH Power Pellets® are designed to perform much longer, up to twelve months.

How to Test the pH of Condensate

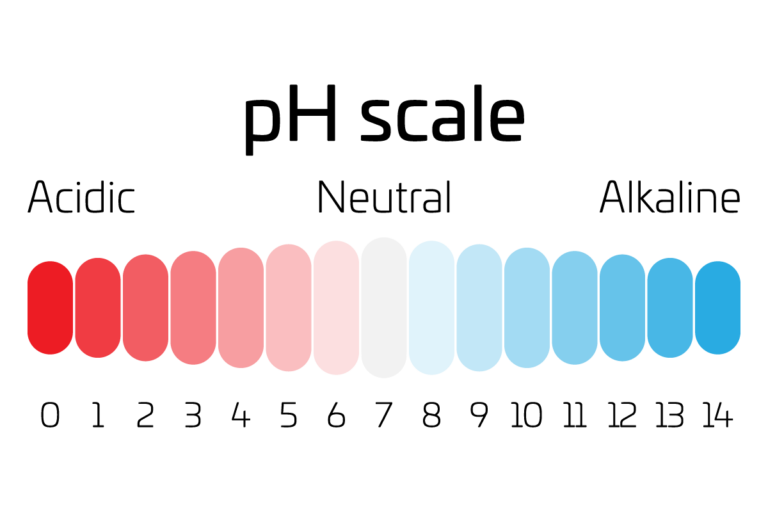

Condensate treated by a neutralizer should have a pH level of at least 5.0, or the level determined by the local water authority code, in order to be safely released. A service technician can test the pH of condensate via two different methods: paper testing strips or a digital pH meter. If the condensate has a pH of less than 5.0, the neutralizer media should be immediately replaced.

pH Paper Testing

Service technicians can use litmus paper strips to determine if condensate is acidic. The paper will change color if the liquid has a low pH.

Technicians can also use pH testing strips, which are more accurate than litmus paper. Instead of informing whether or not the condensate is acidic, it actually defines how acidic the substance is.

When testing pH, technicians should sample the condensate from the outlet and place the strip in the sample container. After a few seconds, the strip can be removed and read using the pH color chart included with the test kit.

This method is inexpensive, but can be prone to human error. Because individuals see colors differently, the person testing may not accurately match the color on the paper to the key. The person testing may also use an expired testing strip or mishandle the strip, resulting in an inaccurate reading.

Digital pH Meter

Digital pH meters use glass electrodes to measure the acidity levels of a liquid. These electrodes are placed inside a container holding the test condensate, and the meter displays the numerical pH value.

In order to receive the most accurate reading, the electrode should be designed to measure low ionic strength samples. Probes should be properly cared for, to avoid malfunction or breakage.

Digital pH meters are more expensive than paper tests, but they are more accurate and easier to read.

Why Routine Maintenance of Neutralizers is Essential

Untreated acidic condensate can quickly eat through copper piping, cast iron pipes, and the concrete foundation in residential and commercial buildings. A neutralizer that is not properly maintained is comparable to not having a neutralizer at all.

Replacing the media inside neutralizers protects buildings and wastewater systems from corrosion. It also ensures compliance with plumbing codes, which prohibit the release of untreated acidic condensate into the wastewater system. At a minimum, service technicians should replace neutralizer media annually.

JJM Alkaline Technologies® designs and manufactures innovative condensate neutralization solutions for residential and light commercial installations. View our collection of acidic condensate neutralizers and replacement pH Power Pellets® here.