Why are Condensate

Neutralizers

Important?

HIGH-EFFICIENCY REVOLUTION: WHY CONDENSATE NEUTRALIZERS ARE CRITICAL

As efficiency standards and innovations increase, heating equipment with condensing technology is rapidly being adopted as a preferred option for residential and commercial installations. These cutting-edge gas boilers, furnaces, and hot water heaters can lower energy consumption and energy bills for homeowners and building owners.

However, these high-efficiency appliances create an often misunderstood residue: acidic condensate. Acidic condensate is a byproduct of the condensing technology that extracts additional heat from the combustion gases, which then cool inside the appliance. Unlike air conditioning condensate, this acidic condensate is corrosive because it includes various acids from burning natural gas (or propane). If discharged untreated, this residue can corrode plumbing, concrete foundations, floor drains, septic systems and other wastewater infrastructure.

With the growing prevalence of these new appliances on the market, many contractors, engineers, and service technicians are unaware of the issue of this acidic condensate and how to efficiently treat it. Industry innovators, like JJM Alkaline Technologies, have developed a purpose-built solution to address this issue: a condensate neutralizer. These condensate neutralizers treat acidic condensate from condensing gas-fired heating appliances so the acidic condensate can be safely discharged from the home or building.

For properties operating with high-efficiency appliances, condensate neutralizers are critical to prevent expensive property damage or even operational shutdown due to code requirements.

How Condensate Neutralizers Work

A condensate neutralizer is a reliable, purpose-built solution, which serves as a filtration device to treat the acidic condensate created from these high-efficiency, gas-fired appliances.

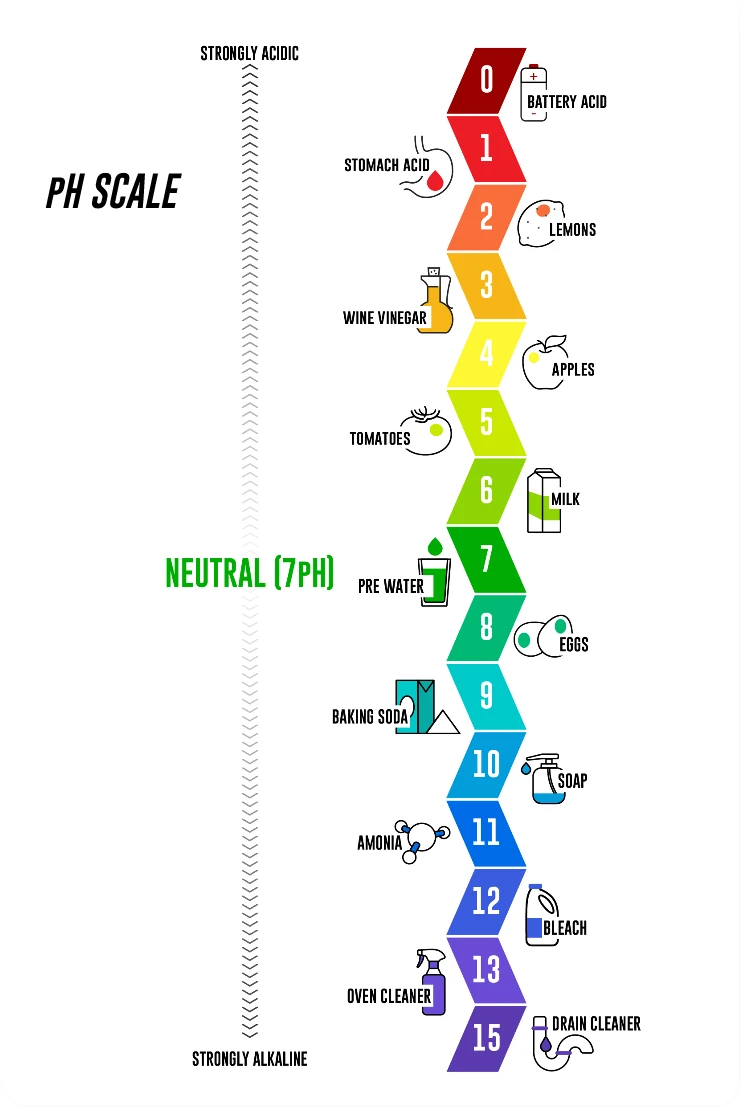

A condensing heating appliance utilizes its secondary heat exchanger to extract heat from exhaust gases, which then condense into a liquid. This condensate has a low pH level, usually between 2.9 and 4.0 pH, which makes it corrosive to floor drains, cast-iron pipes, concrete foundations, sewer lines, and wastewater treatment systems.

Condensate neutralizers contain media that interacts with the condensate to lower its acidity. During effective neutralization:

1 Acidic condensate drains from the high-efficiency appliance and slowly enters the condensate neutralizer

2 Acidic condensate begins to interact with the media inside the device and “soak time” begins

3 The media neutralizes the acidic condensate by raising the pH level to between 5.0 and 9.5

4 The neutralized condensate is then safe to be discharged from the condensate neutralizer into the plumbing or wastewater system

THE STRENGTH OF AN EFFECTIVE CONDENSATE NEUTRALIZER

Early condensate neutralizer solutions were essentially crude and inept instruments, often just a large box filled with marble or limestone chips. Then, companies, such as JJM Alkaline Technologies®, created innovative, purpose-built condensate neutralizer solutions that were extremely efficient and effective.

JJM® offers the largest portfolio of neutralization solutions to safely and effectively treat acidic condensate for residential and commercial installations, such as a large boiler for a hospital or a tankless water heater for a home. With five product series, JJM® products are designed to suit various operating site conditions found in heating and plumbing installations.

JJM® products use pH Power Pellets®, the proprietary neutralizing media found exclusively in JJM® products. The pH Power Pellets® are non-toxic and shelf stable, with magnesium oxide as the active ingredient. The media is loosely distributed throughout the neutralizer to ensure adequate surface area and “soak time” for the acidic condensate to be effectively treated.

View our products

4

Reasons why omitting

condensate neutralizers

is not an option

Condensate neutralizers should be installed with every high-efficiency, gas-fired heating appliance for several compelling reasons.

1. CONDENSATE NEUTRALIZERS PROTECT BUILDINGS AND INFRASTRUCTURE AGAINST EXPENSIVE DAMAGE

Acidic condensate can corrode many building materials, including concrete foundations, sewer lines, or cast-iron pipes common in older homes. Once acidic condensate has been neutralized to a safe pH level (pH 5.0-9.5), it is no longer corrosive. Homeowners and building owners can avoid costly and frustrating repairs by ensuring a condensate neutralizer is installed with their high-efficiency system.

2. PLUMBING CODES REQUIRE THE TREATMENT OF ACIDIC CONDENSATE

Contractors, engineers, and service technicians have an obligation to ensure safe treatment and discharge of acidic condensate produced by condensing gas-fired heating appliances. Due to recent developments, local, national, and industry plumbing codes now prevent the release of corrosive wastes, like untreated acidic condensate, into the wastewater system to prevent the damage that untreated acidic condensate can cause to local plumbing systems.

Contractors and engineers who do not implement a treatment solution for acidic condensate can face consequences if their project or job is inspected, such as fines or operational shutdown.

3. CONDENSATE NEUTRALIZERS SUSTAIN SEPTIC SYSTEMS

Untreated acidic condensate can potentially deteriorate septic systems. When acidic condensate interacts with culture in the septic system, it can impact the good bacteria in the system and impair the septic system’s ability to break down waste.

As a result, septic systems can become backed up or foul.

4. CONDENSATE NEUTRALIZERS MAINTAIN HEALTH OF ENVIRONMENT AND GROUNDWATER

When untreated acidic condensate is discharged onto the ground, it can contaminate and kill vegetation, resulting in dead grass and a ruined garden. Acidic condensate could also pollute groundwater, which often flows into lakes, rivers, and wetlands.