High-efficiency, gas-fired heating appliances (think boilers, furnaces and hot water heaters) are game changing innovations that reduce our environmental footprint and reduce energy costs. However, condensing appliances come with one often overlooked problem: acidic condensate. This is the byproduct of the condensing technology whereby the combustion gases are recaptured, and additional heat is extracted by a secondary heat exchanger. Unlike air conditioning or refrigeration condensate though, this liquid is corrosive due to the hydrocarbons that were burned. If left untreated, this residue can cause serious and long-lasting property damage, wreaking havoc on plumbing, concrete foundations, floor drains, septic systems and other wastewater infrastructure.

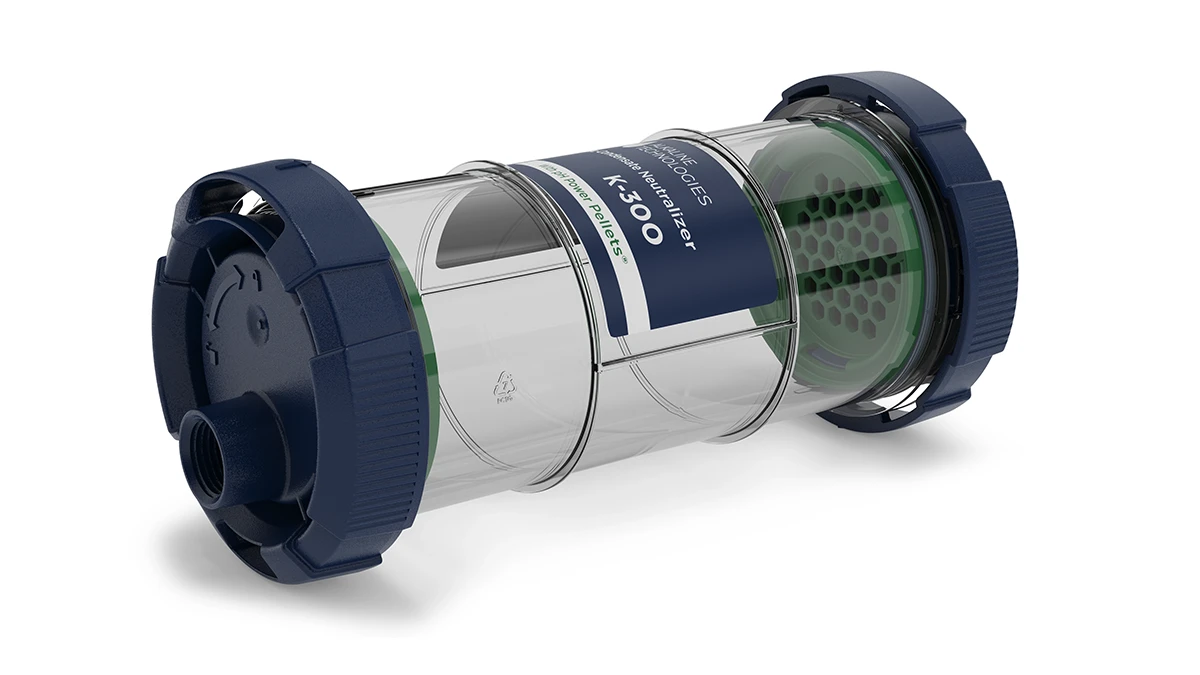

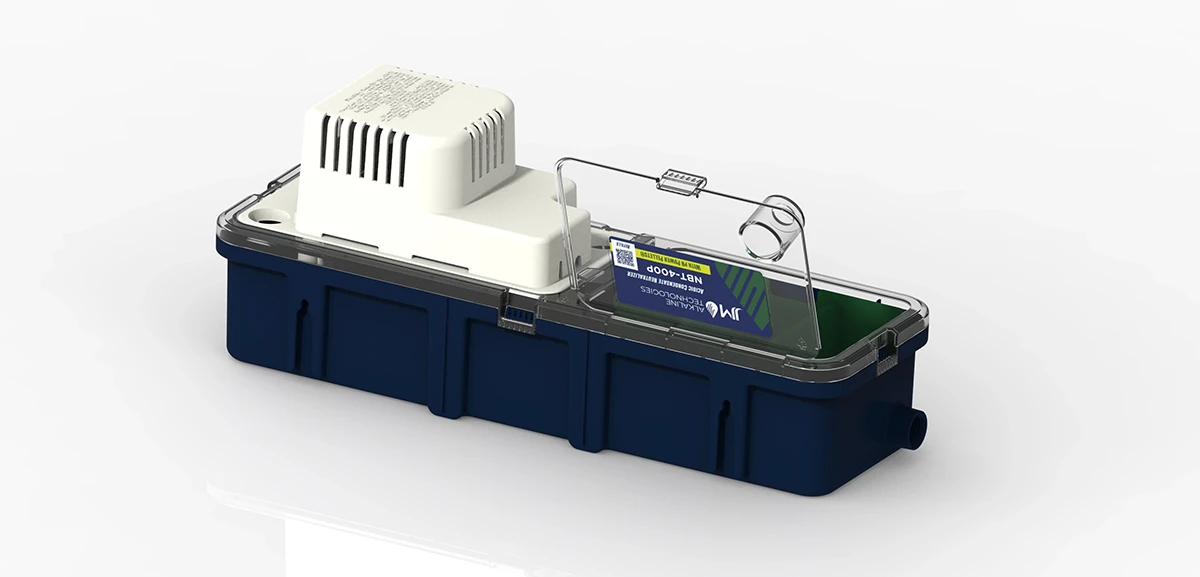

Not to worry though. In most cases, filtration devices called condensate neutralizers are installed with the gas-fired, high-efficiency appliance to ensure protection from this condensate and compliance with disposal codes. Essentially, a condensate neutralizer raises the pH level of the residue (reducing its acidity) to a safe level before the condensate is discharged into the plumbing and wastewater systems. This in turn helps prevent potential property damage.

A critical component of every gas-fired, high-efficiency installation, purpose-built condensate neutralizers are a must-have. So, like any filter, you might be asking yourself: How long does a condensate neutralizer last?

Condensate neutralizers must be routinely inspected and maintained

A properly installed condensate neutralizer can perform effectively in a high-efficiency installation for years, provided the device is routinely inspected and its neutralizing media are replaced regularly. This second point is key. Various factors, such as the acidity and volume of the condensate produced, can impact the longevity of the neutralizer’s media. To ensure continued protection, professional service technicians should routinely test the pH of the treated condensate leaving the neutralizer to make sure the pH remains greater than 5.0 (or possibly higher with local code requirement). The service technician should immediately replace the neutralizing media if the pH level reads below the minimum level. Generally, the media should be replaced at least every twelve months. As a best practice, service technicians should incorporate this neutralizer service into the preventative maintenance program for the high-efficiency appliance.

Not all neutralizer media is created equal, though. For reference, condensate neutralizers from JJM® use pH Power Pellets®, the proprietary media found exclusively in JJM® neutralizers. pH Power Pellets® are sold as individual kits and sized by JJM® model to ensure quick and accurate routine replacement every time.

We’ve got you covered

Many professional service technicians around the country trust condensate neutralizers by JJM Alkaline Technologies. Purchase JJM® condensate neutralizers and our pH Power Pellets® refills from authorized distributors of heating and plumbing equipment across the United States and Canada. Use our distributor finder to locate your nearest JJM® authorized wholesaler.

To learn more about why condensate neutralization is critical on every condensing installation, check out our Resources page.