High-efficiency, gas-fired heating appliances (i.e. 90+% boilers, furnaces and hot water heaters), are without a doubt game-changing innovations that reduce home and building energy costs and our environmental footprint.

Still, even with the growing prevalence of these high-efficiency installations, some HVAC and plumbing contractors are unaware of the acidic condensate issue associated with condensing appliances. Acidic condensate is a byproduct of the condensing phase in high-efficiency, gas-fired heating appliances whereby the secondary heat exchanger extracts additional heat from the combustion gases, which then cools into a liquid. Unlike HVAC condensate that you’d see rolling off the coils in an air conditioning unit, acidic condensate is corrosive (with low pH of 2.9-4.0) because it includes various acids from burning natural gas (or propane). If discharged untreated, homeowners and building owners may be left dealing with the costly consequences of acidic condensate corrosion.

Here are the three most expensive kinds of damages caused by acidic condensate that has not been properly treated.

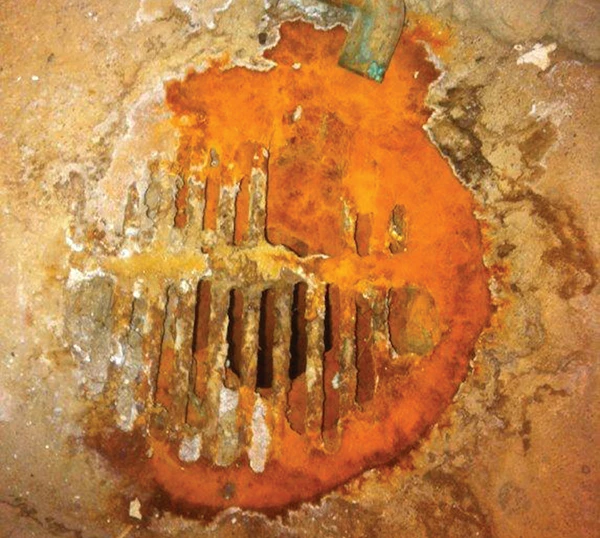

#1: Acidic condensate can damage floors, floor drains and concrete foundation

If untreated acidic condensate is discharged to a floor drain, this residue will discolor and eventually corrode the floor, floor drain, and concrete foundation (like you can see in the below image). Such damage could potentially cost thousands of dollars to repair.

Photo Credit: PHCP Pros

#2: Acidic condensate can damage plumbing systems

Because of its acidic nature, acidic condensate can eat away at various metals that are commonly used in plumbing systems. For example, cast-iron pipes, which are often the standard in older homes, do not stand a chance against acidic condensate, which eventually will erode corrode the piping.

Photo Credit: Controlled Combustion

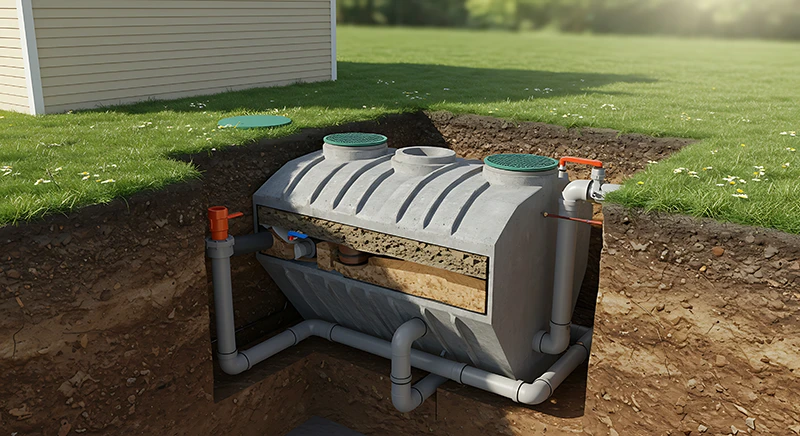

#3: Acidic condensate can damage septic systems and wastewater infrastructure

Untreated acidic condensate can damage sewer lines and wastewater treatment infrastructure. Similarly, acidic condensate can harm septic systems. The acidic condensate can impact the bacteria culture and impair the septic system’s ability to break down waste. As a result, septic systems can become backed up or foul-smelling. Anyone who has dealt with septic system issues before can empathize with the headache and exorbitant bill associated with septic system maintenance and repair.

Condensate neutralizers will prevent damage caused by acidic condensate

So, how can installers and/or service technicians prevent this costly damage caused by acidic condensate corrosion? The solution is simple. A condensate neutralizer should be installed with every high-efficiency, gas-fired heating appliance. Condensate neutralizers are filtration-like devices purpose-built to treat this acidic condensate by raising its pH to a safe level (pH 5.0-9.5), rendering it no longer harmful to the plumbing system. JJM Alkaline Technologies® is the industry pioneer and leading manufacturer of condensate neutralizers. We built the pHIRST one twenty years ago. Now, we build the best ones on the market.

Preventing such damage from acidic condensate is a compelling reason to install JJM® condensate neutralizers on every high-efficiency heating appliance. However, it’s also required by code. The 2018 and 2021 editions of the International Plumbing Code (IPC) prohibit the release of corrosive wastes, like untreated acidic condensate, into the wastewater system without proper treatment. As such, the IPC makes JJM® condensate neutralizers a key to achieving code compliance on all high-efficiency, gas-fired installations.

Next steps

To learn more about why JJM® condensate neutralizers are a must-have accessory to prevent the kinds of damages caused by acidic condensate and ensure code compliance, visit our resource page.

To purchase from a JJM® authorized distributor, click on our “Where to Buy” page. If your preferred distributor doesn’t stock JJM® yet, ask them to contact us (ask for the Blue Label).