Did you know that the average residential, gas-fired, high-efficiency heating appliance will produce approximately 2 gallons per hour of acidic condensate? That’s nearly an estimated 9 billion gallons of acidic condensate that condensing appliances are churning out every year in the U.S. Yikes. That’s a lot of potential damage to property and the environment.

Let’s give some context to this daunting statistic. Today’s gas-fired, high-efficiency heating appliances (think boilers, furnaces or hot water heaters) achieve their sought-after energy-efficient performance (90+%) by extracting heat from exhaust gases. As these gases cool down, the vapor hits the dewpoint and turns into a liquid. Unlike air conditioning condensate, though, this condensate is acidic (2.9-4.0 pH) due to the hydrocarbons that were burned. If discharged without being properly treated, acidic condensate can corrode plumbing, concrete foundations, floor drains and wastewater systems, and pollute groundwater and the environment.

How do condensate neutralizers work in high-efficiency appliances?

So, what’s the solution to this dilemma? Purpose-built filtration devices called condensate neutralizers are installed with the high-efficiency appliance. These filtration devices raise the pH of the acidic condensate (reducing its acidity) to a safe level, hitting somewhere between 5.0 and 9.5 pH. This in turn helps prevent potential damage to property or the surrounding environment. As such, condensate neutralizers are a must-have accessory on every condensing installation to ensure that the high-efficiency appliance operates safely and fulfills its environmental promise.

Start with choosing the right neutralizer

In order to ensure protection from this residue, it’s important to choose the right condensate neutralizer for the appliance. Some of the variables that factor into this decision include the BTU input of the heating appliance and its efficiency rating, the composition of the raw gas being burned, the operating site conditions and the number of annual hours the heating appliance will be in operation. Learn more about choosing the best condensate neutralizer for your installation here.

Don’t forget to prioritize regular maintenance

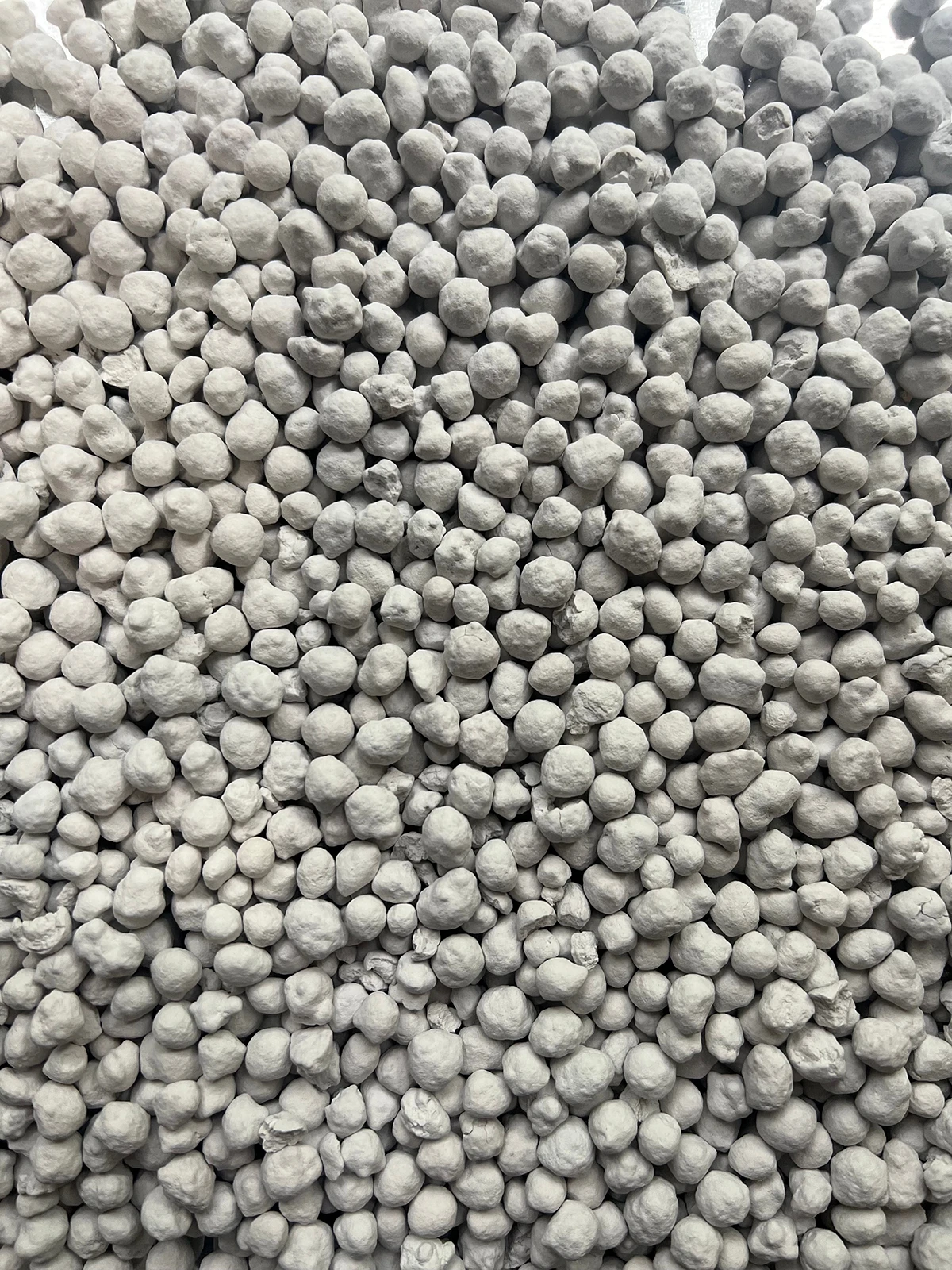

Of course, it’s recommended that gas-fired, high-efficiency appliances receive annual maintenance. And just like the heating appliance itself, the condensate neutralizer device also needs to be routinely serviced to ensure continued protection and code compliance. Professional HVAC or plumbing service techs can test the pH of the treated condensate leaving the filtration device and will then replace the neutralizing media when needed. Keep in mind that not all neutralizer media is created equal. JJM® condensate neutralizers use pH Power Pellets®, the proprietary media found exclusively in JJM® products. pH Power Pellets® are shelf-stable and non-toxic, with magnesium hydroxide as the active ingredient. They are also long-lasting and won’t “waste away” into silt like other neutralizing media. Read more about the media in a JJM® condensate neutralizer here.

Next steps

A critical component on every gas-fired, high-efficiency installation, purpose-built condensate neutralizers are a must-have device for the safe treatment of acidic condensate. Click here to learn more about protecting property and the environment with JJM® products.