Acidic condensate is produced by today’s gas-fired, high-efficiency appliances like boilers, furnaces or hot water heaters. You’d be surprised by how many installers and service technicians don’t realize the dangers of sending this acidic condensate into the plumbing system untreated. Unlike air conditioning condensate, this particular liquid is corrosive due to the hydrocarbons that were burned. Some don’t realize the potential harm. Others are unaware of the code requirements. But if discharged untreated, this residue can cause significant damage, wreaking havoc on plumbing, concrete foundations, floor drains and wastewater systems, and pollute groundwater and the environment. So, what’s the solution? It’s simple. A condensate neutralizer should be installed with every gas-fired, high-efficiency heating appliance.

A purpose-built device, JJM® condensate neutralizers effectively treat the acidic condensate as it leaves the gas-fired, high-efficiency appliance, raising its pH to a safe level to be released into the plumbing system or surrounding environment.

But here’s the thing. While installing the neutralizer itself is critical, it’s only part of the equation. Like the gas-fired heating appliances they service, condensate neutralizers also need routine maintenance. In particular, the condensate neutralizer media, which interacts with the acidic condensate inside the device, also deserves our attention. Here are some of the most commonly asked questions we receive in the field about neutralizing media.

Q: What is the media in a condensate neutralizer?

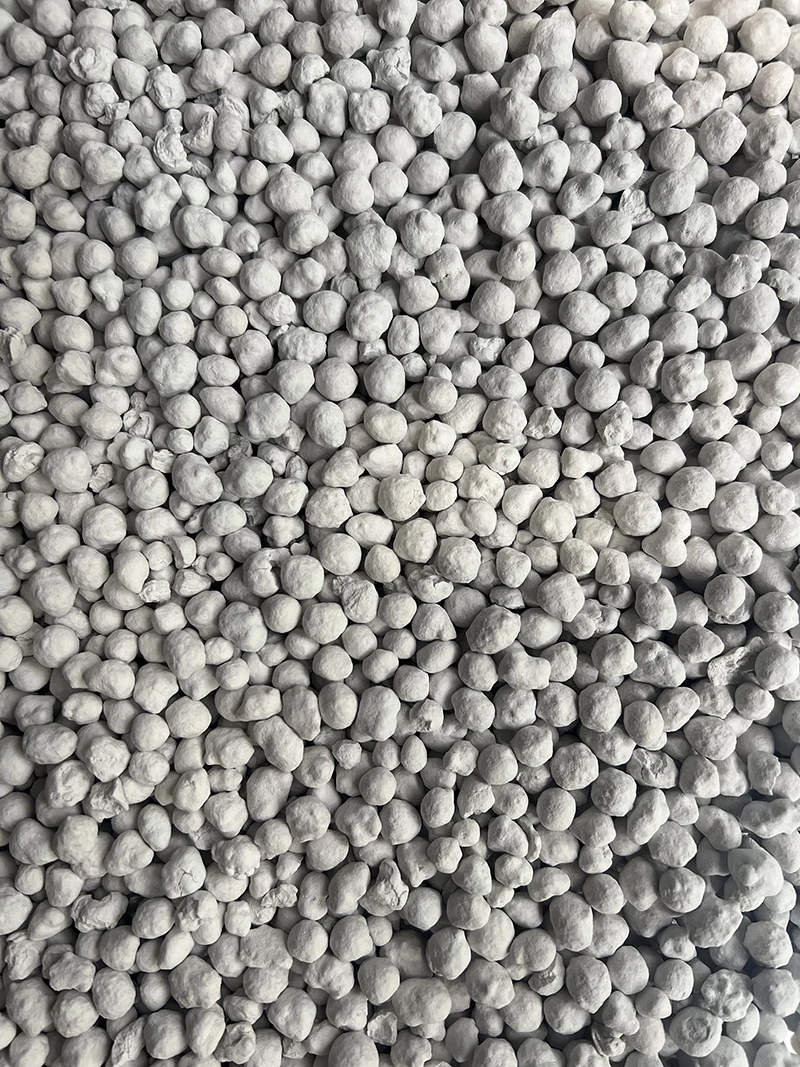

A: Not all neutralizer media is created equal. JJM® condensate neutralizers use pH Power Pellets®, the proprietary media found exclusively in JJM® products. pH Power Pellets® are shelf-stable and non-toxic, with magnesium hydroxide as the active ingredient. pH Power Pellets® are long-lasting and won’t “waste away” into silt like other neutralizing media.

Q: When should I replace condensate neutralizer media?

A: Various factors, such as the acidity and volume of the condensate produced, can impact the longevity of the neutralizer’s media. To ensure continued protection, service techs should routinely test the pH of the treated condensate leaving the neutralizer to make sure the pH remains greater than 5.0 (or possibly higher with local code requirement). The service tech should immediately replace the neutralizing media if the pH level reads below the minimum level. Generally, the media should be replaced at least every 12 months. As a best practice, service techs should incorporate this neutralizer service into the preventative maintenance program for the gas-fired, high-efficiency appliance.

Q: How do I replace condensate neutralizer media?

A: JJM® condensate neutralizers are designed for quick and easy service. For example, model NBT-400P features a removeable tray that enables the service tech to replace the media without disconnecting any fittings or digging out the old media. In addition, JJM®’s pH Power Pellets® refills are sold as individual kits and sized by JJM® model to ensure quick and accurate replacement every time. No need to waste time guessing how much media to use. To ensure continued performance, service techs should procure the correct refill kit as JJM® condensate neutralizers are designed and rated with the specific pH Power Pellets® media.

Next steps

Purchase JJM® condensate neutralizers and pH Power Pellets® refills from authorized distributors of heating and plumbing equipment across the United States and Canada. Use our distributor finder to locate your nearest JJM® authorized wholesaler.