Home heating season is in full swing. For HVAC contractors, installers and service technicians, this means a packed calendar of service calls and annual maintenance on home heating appliances. This is also the ideal time to ensure a condensate neutralizer is properly installed and maintained on every high-efficiency, gas-fired furnace or boiler. Doing so is key to mitigating the acidic condensate issue associated with today’s condensing appliances. But most homeowners are unaware of these risks or the must-have accessory needed to treat it: condensate neutralizers. It’s your job to educate them.

Here are some key talking points to inform the homeowner, help prevent costly damage from condensate corrosion, and capitalize on this recurring service opportunity.

KEY TALKING POINT: WHAT IS ACIDIC FURNACE CONDENSATE

First, lay the foundation for your customer. Acidic condensate is a byproduct of the condensing phase in high-efficiency, gas-fired heating appliances (think 95% furnaces) whereby the secondary heat exchanger extracts additional heat from the combustion gases, which then cools into a liquid. Explain that unlike HVAC condensate that they might see rolling off the coils in their AC unit, acidic furnace condensate is highly corrosive (with low pH of 2.9-4.0) because it includes various acids from burning natural gas (or propane).

KEY TALKING POINT: TYPES OF DAMAGE CAUSED BY ACIDIC FURNACE CONDENSATE

It’s very important that homeowners understand that if discharged untreated, they may be left dealing with the consequences of acidic condensate corrosion. Remind your customer that the top three most expensive damages caused by acidic condensate corrosion include:

- Damage to floors, floor drains and concrete foundation

- Damage to the plumbing system

- Damage to sewer lines, the septic system and wastewater treatment infrastructure

KEY TALKING POINT: WHAT FURNACE CONDENSATE NEUTRALIZERS ARE AND HOW THEY WORK

Give your customer the good news. Installing a purpose-built solution called a condensate neutralizer will prevent these types of damages caused by untreated acidic condensate. A condensate neutralizer is a filtration-like device that raises the pH level of the acidic furnace condensate (reducing its acidity) to a safe level before it’s discharged into the plumbing and wastewater systems. One should be installed with every high-efficiency, gas-fired furnace or boiler.

Contractors, installers and service technicians trust and recommend JJM® condensate neutralizers to their customers. JJM Alkaline Technologies® is the industry pioneer and leading manufacturer of condensate neutralizers. We built the pHIRST one twenty years ago. Now, we build the best ones on the market.

KEY TALKING POINT: CONDENSATE NEUTRALIZERS ARE REQUIRED BY CODE

Preventing damage caused by acidic furnace condensate should be reason enough to install JJM® condensate neutralizers on every high-efficiency, gas-fired furnace. After all, what homeowner wants to be stuck with a steep repair bill? But in most of the U.S., it’s also a code requirement. Let your customer know that the EPA prohibits the release of corrosive wastes (defined as a pH level below 5.0) into the public sewer system. Further, due to recent code developments, most jurisdictions now require a neutralizing device to treat corrosive wastes before they are discharged into the public wastewater system. This makes condensate neutralizers a must-have accessory on every high-efficiency, gas-fired furnace to achieve code compliance.

KEY TALKING POINT: HIGH-EFFICIENCY FURNACE MAINTENANCE IS EASY

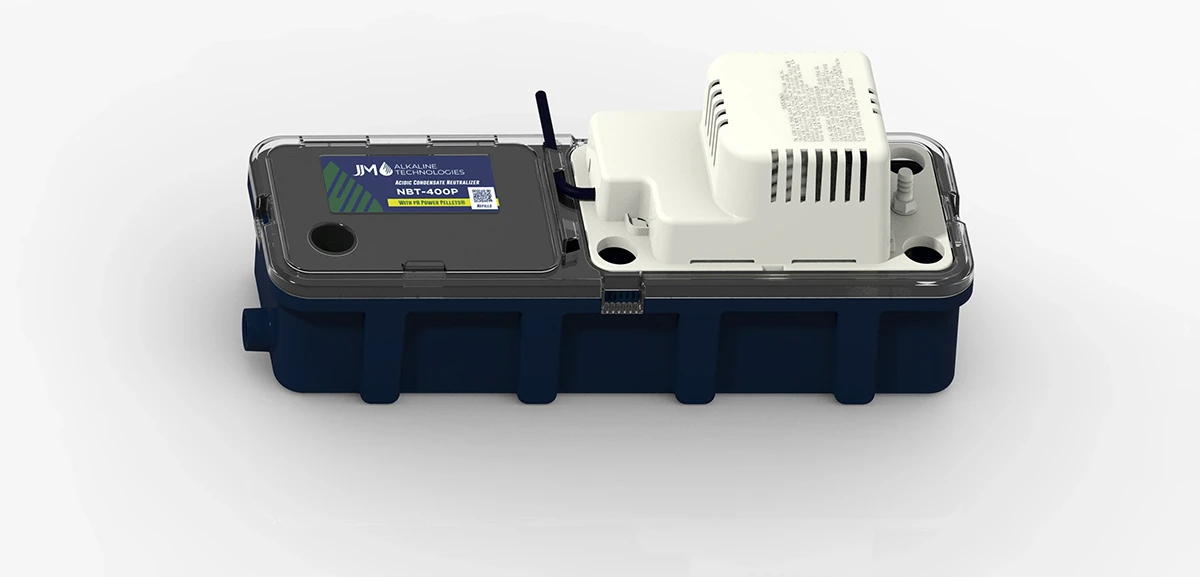

Just like gas heating appliances, condensate neutralizers also need to be routinely serviced. Generally, JJM® recommends that service technicians replace the condensate neutralizer media at least every 12 months. Service technicians can build the condensate neutralizer service into the annual preventative maintenance program for a high-efficiency, gas-fired furnace or boiler. For example, a service technician can service the JJM® NBT-400P condensate neutralizer (designed to be quickly and efficiently serviced without disconnecting any fittings) by replacing the pH Power Pellets® during a furnace tune-up and inspection. If a condensate neutralizer was not previously installed with the condensing furnace, a savvy service technician can quickly install a JJM® condensate neutralizer during the furnace service call.

NEXT STEPS

Home heating season is here…and JJM® wants to set you up for success. Want to get your team trained by the industry pioneer in condensate neutralizer solutions? Request a training session from JJM® today. Want to buy the best? Click on our “Where to Buy” page to track down a JJM® authorized distributor. If your preferred distributor doesn’t stock JJM® yet, ask them to contact us (ask for the Blue Label).