Today, most HVAC industry pros have a renewed focus on preventive maintenance programs and service contracts to not only help mitigate the ownership costs of new, modern HVAC equipment, but also to deliver recurring service revenue for their businesses. With the advent of high-efficiency, gas furnaces there is an emerging maintenance opportunity: condensate neutralizers.

High-efficiency, gas furnaces go mainstream

As homeowners look to reduce their energy consumption, many are selecting a high-efficiency gas furnace, even in milder climates. These furnaces, with an annual fuel utilization efficiency of at least 90%, can improve comfort inside the home, reduce reliance on the energy grid, and lower energy bills. The push towards high-efficiency furnaces is underscored by the U.S. Department of Energy’s new efficiency standard for residential gas furnaces, which will require new non-weatherized gas furnaces to achieve an efficiency of at least 95% beginning in 2028.

As more homeowners across the country make the switch to these high-efficiency furnaces in the coming years, HVAC industry pros will need to be prepared to properly install and maintain these new systems—including how to manage a by-product of this new technology: acidic condensate.

Secondary heat exchanger and acidic condensate

The modern, high-efficiency gas furnaces achieve such efficiency by utilizing “condensing” technology. Condensing furnaces incorporate a secondary heat exchanger to extract additional heat from the combustion gases, which then cool and condense into a liquid. Unlike air conditioning condensate, this residue is acidic (e.g. pH of 2.9-4.0) and can corrode plumbing, concrete foundations, floor drains and wastewater systems, and pollute groundwater and the environment.

However, the solution for acidic condensate is simple: install a condensate neutralizer with every condensing furnace. A condensate neutralizer is a filtration device purpose-built to efficiently and effectively treat the acidic condensate from gas furnaces and prevent potential damage.

Installing a condensate neutralizer with every high-efficiency furnace is not just about protecting facilities and the environment. In most of the U.S., it is also a code requirement. The EPA prohibits the release of corrosive wastes (defined as a pH level below 5.0) into the public sewer system. Further, due to recent code developments, most jurisdictions now require a neutralizing device to treat corrosive wastes before they are discharged into the public wastewater system.

As such, condensate neutralizers are a must-have accessory on every condensing furnace installation to achieve code compliance and ensure that high-efficiency appliances fulfill their environmental promise.

Condensate neutralizers for HVAC pros

Not all condensate neutralizers are created equally though. To deliver for their customers, leading HVAC pros must work with the best products to ensure an efficient, cost-effective installation and service. JJM® is the industry pioneer and today’s leading manufacturer of condensate neutralizers for the heating and plumbing industries. JJM® products are designed with industry pros in mind: versatile to install, quick and easy to service, and purpose-built for specific applications, like a high-efficiency furnace.

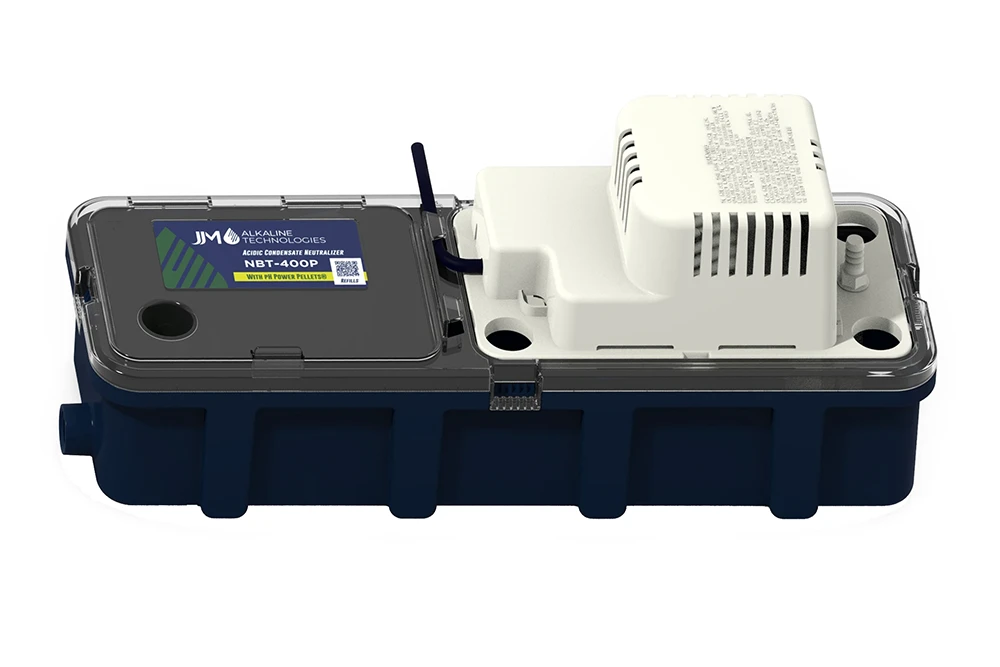

For example, the JJM® NBT-400P is one of the best condensate neutralizers for condensing furnaces. Equipped with a built-in condensate pump, the NBT-400P model provides an all-in-one solution for efficient neutralization and disposal to a remote drain. This model is popular with HVAC pros because it can handle both acidic condensate and non-acidic condensate from the evaporator coil. In addition, the NBT-400P features a removeable tray that ensures quick and easy replacement of the pH Power Pellets® media without disconnecting any fittings.

Recurring service revenue built-into HVAC annual maintenance

Like any filtration device, condensate neutralizers must be routinely serviced to maintain effectiveness and code compliance.

JJM® condensate neutralizers, like the NBT-400P, are designed to be quickly and efficiently serviced. They are built with pH Power Pellets®, JJM®’s proprietary neutralizing media found exclusively in JJM® products. pH Power Pellets® refill kits are individually weighed and packaged for each JJM® condensate neutralizer model, which ensures quick and accurate service every time. No guesswork required in the field.

Generally, JJM® recommends that service technicians routinely service the condensate neutralizer by replacing the neutralizer media at least every 12 months. However, every installation varies based on the furnace BTU capacity, operating hours, and acidic condensate produced.

To ensure a condensate neutralizer is performing, a service technician should test the pH of treated acidic condensate with a digital pH meter. If the pH is lower than 5.0 (or the local water authority threshold), then the technician should immediately replace the neutralizer media. Let’s be honest: it might not be cost-effective for a homeowner to call a service technician out simply to test the pH.

As such, best-in-class HVAC service technicians will simply build the condensate neutralizer service into the annual preventative maintenance program for a condensing furnace. For instance, a service technician can quickly service the NBT-400P condensate neutralizer by replacing the pH Power Pellets® during a furnace tune-up and inspection done before the start of heating season.

But what if a condensate neutralizer was not previously installed with the condensing furnace? A savvy HVAC service technician can quickly install a JJM® condensate neutralizer during the furnace service call. Boom! Crisis averted and maintenance done.

Condensate neutralizers are not only critical to protecting facilities and the environment, but they present a huge maintenance opportunity for HVAC pros with installation and recurring service.

Ask for the Blue Label

Those who know, know to Ask for the Blue Label. As the industry pioneer, JJM Alkaline Technologies® has been supplying HVAC industry pros with reliable, purpose-built condensate neutralizers to effectively treat acidic condensate for 20 years. Importantly, JJM® condensate neutralizers are Made in America. We built the pHirst one. Now, we build the best ones. Why settle for anything less?

Want to get your team trained by the industry pioneer? Request a training from JJM® today.

Want to buy the best? Find an authorized JJM® distributor near you to purchase our industry-leading solutions here.